Welcome!

As a freelance engineer, I create something new every day in my workshop in Dresden, Germany.

With high standards and expertise, I develop technical solutions, build prototypes and small production runs and design customized processes. I bring new ideas both in to customer requests and my own projects.

Technology

Here I explain the available technologies and present the possibilities with which your project can be realized in my workshop.

Technical design and planning

I design devices, jigs, machines such as storage, transfer and handling systems, grippers, forming tools and mechanisms of all kinds for you. I incorporate modern design aspects such as compliant design and am very capable in free-form modeling. My service naturally also includes comprehensible documentation and is based on all standards relevant to the Machinery Directive.

3D-Printing

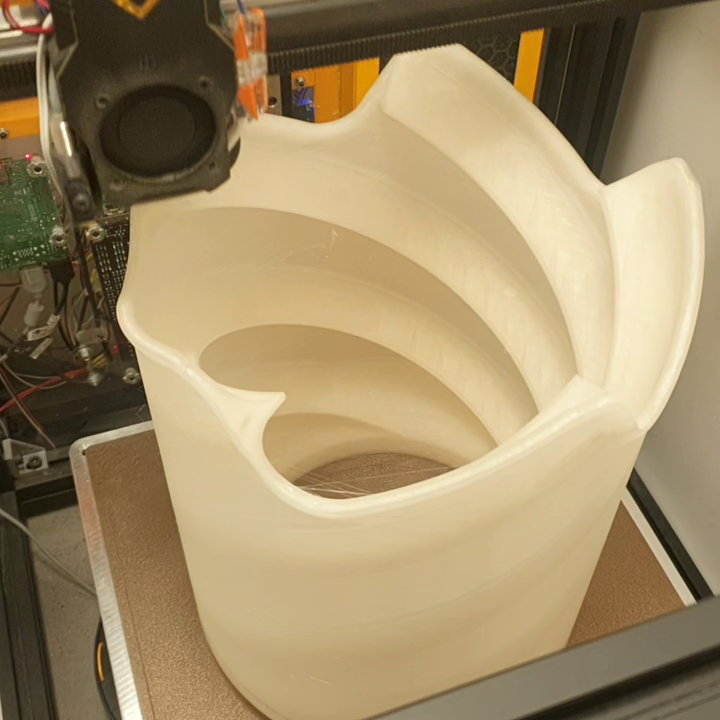

The an important foundation for most projects is 3D printing. Not only for figurines and sculptures, but especially for customized jigs and fixtures, moulding tools and complex machine elements that are in no way inferior to the quality of injection moulding, 3D printing can be used in a time and cost-effective manner.

Metal Casting

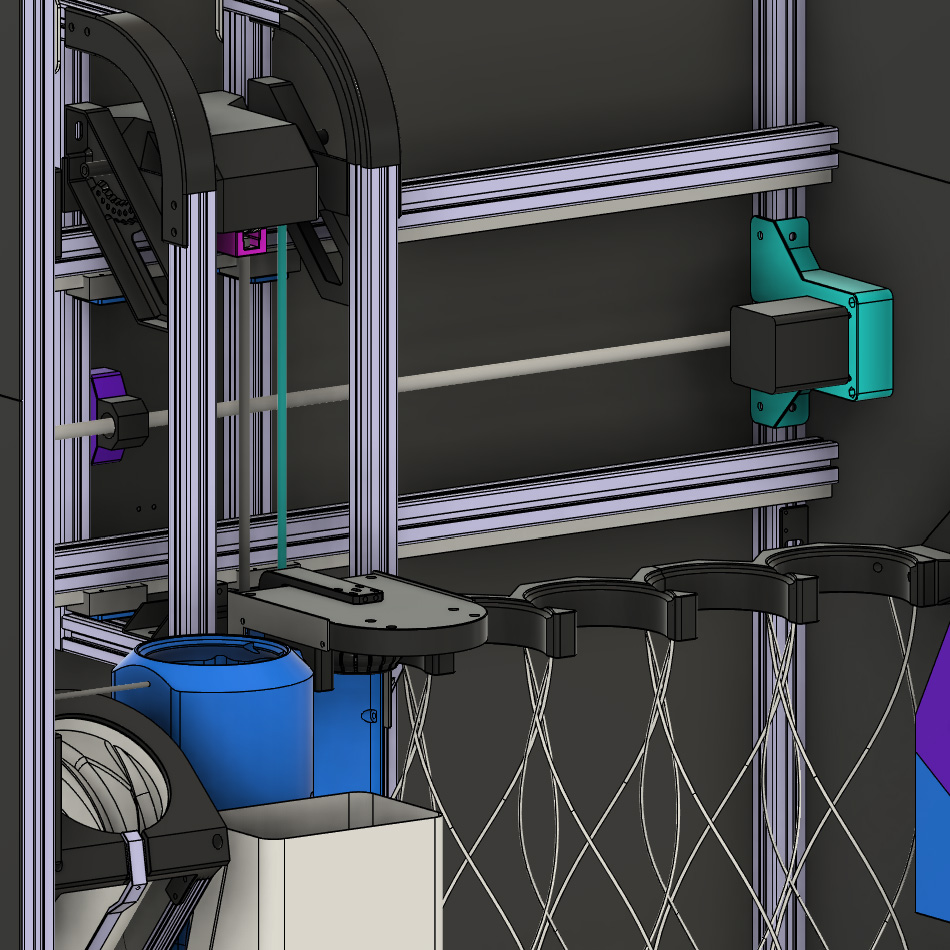

Plastic is practical and versatile, but it cannot replace metal. I can shape aluminum, copper, bronze or brass for you. To do this, I use investment casting with the lost form method that conserves resources by embedding them in a thin ceramic shell. The shells grow with reliable quality in an automation system that was developed in-house.

Smooth Plastic Coating

To avoid transferring the surface lines typical to FDM 3d-printing to the cast parts, I have developed my own coating system that can be burned away without any ash and without harmful emissions. By further optimizing the process, I can now also offer it directly for refining any 3D-printed surfaces. As it is an immersion process, the coating also works in highly angled interior areas that cannot be reached with sandpaper and brushes. Pigment additives can also be used to create colored coatings in a range of glossy or matt finishes.

Moldmaking

I reproduce conventionally modeled clay masters of sculptures and objects in silicone molds for metal or resin casting in all applications where a digital model cannot be used. Composite materials (carbon fiber, glass fiber) and PU foams can also be precisely shaped in this way.

Design Work

I demonstrate the almost limitless creative freedom that metal casting from 3d prints offers in my current main creative project: bronze chess pieces. With their optimized weight, excellent balance, unique sound, texture and silky sheen, my pieces offer a playing experience that can’t be found anywhere else.

What started as a hobby project to test my skills has now grown into a design brand in its own right. Learn more about the project on its own website at Taboto Studio, where you can also order them directly from my own store.

About Me

Even in my youth in Leipzig, I was always the tinkerer and inventor with a desk full of notes with sketches and calculations. Coming from a family of engineers, my degree in mechanical engineering at the TU Dresden was almost a formality. Even during my studies, the projects got bigger, my self-confidence grew and the toys got more expensive.

Shortly before the pandemic, I started my first job as a automation engineer at a company that specialized on carbon fiber parts. In the first few years of work, I had the incredible opportunity to spend most of my time programming robots and designing tools and whole machines. Oh this freedom and accomplishment!

Now I’m about to take the next big step: my own workshop.

Contact Me!

If I have caught your interest, if you already have a project in mind, or if you simply want to express praise or criticism, then write to me! Even if you don’t yet know exactly what you want or need, I always have an open ear / space in my inbox for you.